Pipeline welding construction

Double-torch pipeline automatic external welding system

Equipment model:YH-A21

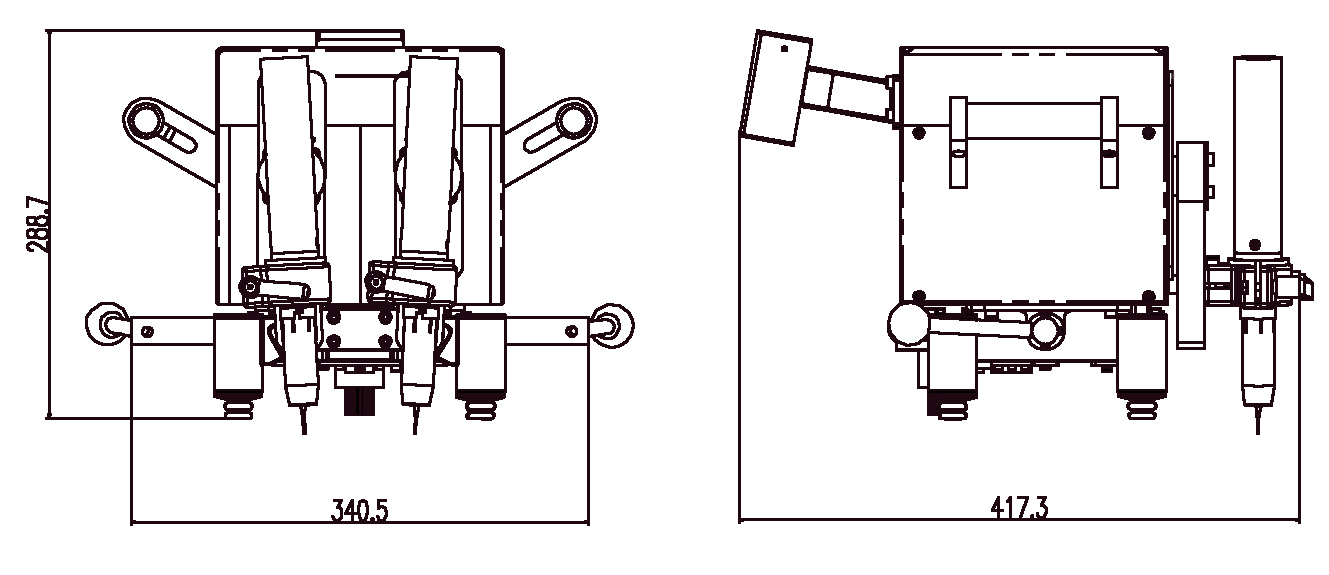

Equipment size:340*420*300(mm)

Equipment weight:40kg

Upload time:2023-02-27 09:40:11

Product description:Yuehong double-torch pipeline automatic external welding system YH-A21 has compact structure, complete functions, and is···

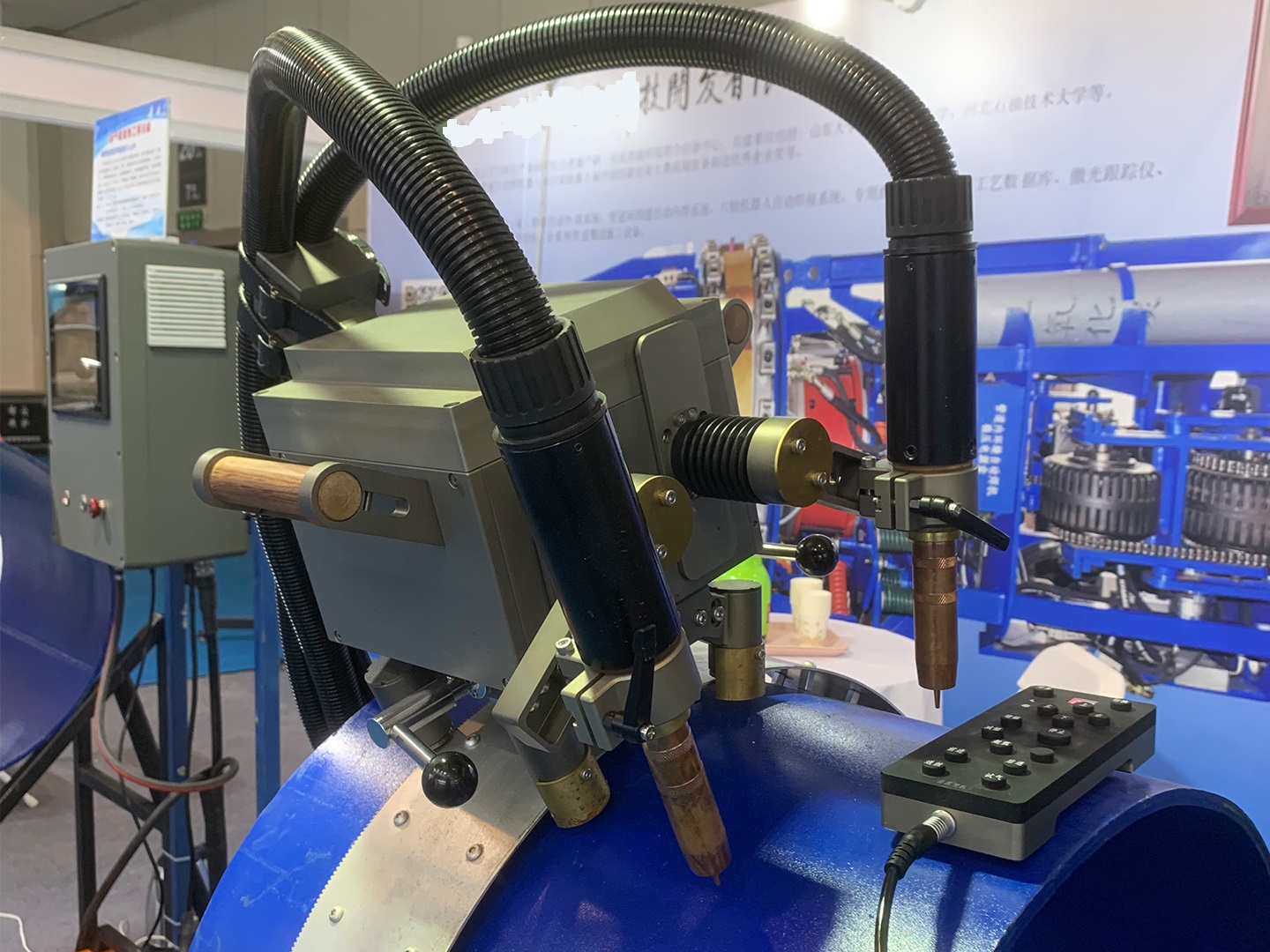

Double-torch pipeline automatic external welding system YH-A21

All-position automatic pipe welding equipment

Standard configuration:

automatic pipe welding equipment (one set)

one control system,

one control cable set,

two welding power supplies,

two welding guns,

one flexible rail,

one protective gas system.

Yuehong double-torch pipeline automatic external welding system YH-A21 has compact structure, complete functions, and is stable and reliable. It can make the laying of onshore and offshore pipelines more efficient and high-quality. The double-torch automatic welding system is a new generation of efficient automatic welding equipment for pipes, which can realize automatic selection of welding process, automatic tracking and adjustment of welding torch position, reduce manual intervention, improve welding quality, and improve welding efficiency through simultaneous construction of double welding beads.

technical parameter

Working mode: manual/automatic

Applicable pipe diameter: ≥ φ 508 mm

Weld width: ≤ 30 mm

Traveling speed: 0 - 5 m/min

Diameter of welding wire: φ 0.8 ~ 1.2 mm

Applicable working conditions:

Large and medium diameter circumferential weld; Applicable pipe diameter ≥ Φ 508mm; Pipe root welding, hot welding, filler welding and cover welding; Weldments such as pipes, curved surfaces and straight surfaces; Vertical and horizontal joints of vessels, storage tanks and other structures, and overlap welds of the vault; Oil and natural gas trunk lines; Water conservancy pipeline.

Particularly applicable:

High requirements for construction quality and efficiency, narrow gap groove and multi-layer weld bead.

Features:

The double-torch pipeline automatic external welding system is equipped with accurate digital controller;

Master core technology, automatic selection and storage of welding process, automatic tracking and adjustment of welding torch position;

Customized manual operation box, more intelligent and more humanized;

It can store tens of thousands of sets of welding parameters and call them at any time as needed;

The automatic monitoring platform for connecting construction welding data can be configured;

Master the core technology: welding expert control system+welding seam tracking process.

Automatic internal welding system of pipeline girth weld

Control system、Hand box、Wire feed box

On-site welding picture

Products

Contact Us

Contact:Jenny Lee

Tel:+86-13132401909

Tel:+86-13132401909

Email:shirley9@pipesitesolution.com

Address: Zhongguancun Industrial Collaborative Innovation Base, Hengshui City, Hebei Province