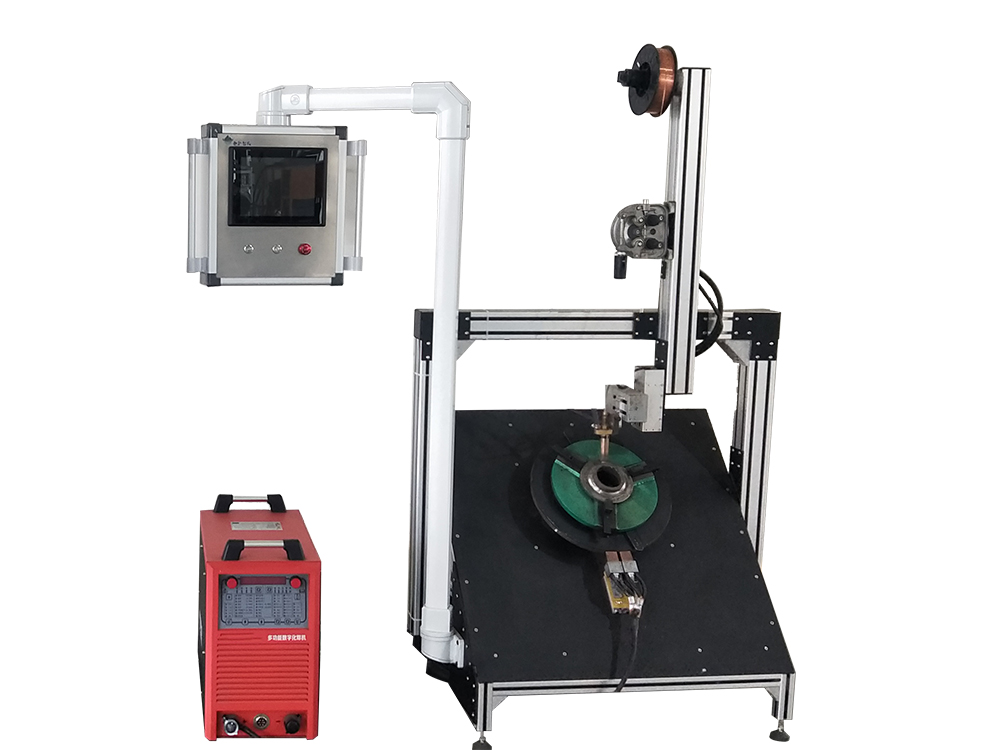

Intelligent welding special equipment

Special welding system for pipe-pipe welding of pressure pipeline components

Equipment model:YH-GGH

Equipment size:customized

Equipment weight:to be confirmed

Upload time:2023-03-04 15:09:10

Product description:The welding function is controlled by a fully automatic welding computer to realize workpiece rotation, current size con···

Special welding system for pipe-pipe welding of pressure pipeline components

YH-GGH

Improve welding efficiency

Improve welding accuracy

Reduce labor intensity

lower production cost

Application scenario:

Automatic welding with high efficiency and precision.

Applicable to:

Welding of pressure vessels and pressure pipeline components, butt or plug welding of pipe-pipe and pipe-bend.

The preliminary requirements for the workpiece: ensure that the weld joint of the workpiece is flush, and remove the machining burr and oil stain. Ensure that the accuracy and consistency of the workpiece do not affect the welding process requirements.

The welding function is controlled by the fully automatic welding computer to realize the rotation of the workpiece, the control of the current size, the control of the feeding speed wire, and the welding speed. With the yaw and seam tracking system, the welding requirements can be met. Thus, the operation level of the welder is reduced, and it is unnecessary to hire highly skilled welders.

Welding method: argon arc welding, gas shielded welding, etc

Pipe diameter range: 30-1200mm

Pipe material: stainless steel, carbon steel and other alloy steel

Welding current: 350A

Voltage: 380V/50Hz

Welding method: adding wire or self-melting

Products

Contact Us

Contact:Jenny Lee

Tel:+86-13132401909

Tel:+86-13132401909

Email:shirley9@pipesitesolution.com

Address: Zhongguancun Industrial Collaborative Innovation Base, Hengshui City, Hebei Province