Technology News

pipeline anti-corrosion coating peeling testing equipment features

From the perspective of a client-side engineering expert, the selection ofpipeline anti-corrosion coating testing equipment is critical to ensure the longevity and safety of pipeline infrastructure. The pipe coating peeling testermust deliver not only in terms of precision and compliance with stringent international standards but also in user experience and data management. Here are the requirements for such equipment, reflecting the features of our coating peeling tester:

From the perspective of a client-side engineering expert, the selection ofpipeline anti-corrosion coating testing equipment is critical to ensure the longevity and safety of pipeline infrastructure. The pipe coating peeling testermust deliver not only in terms of precision and compliance with stringent international standards but also in user experience and data management. Here are the requirements for such equipment, reflecting the features of our coating peeling tester:

1. Standard Compliance: The coating peeling tester should be engineered in strict adherence to international standards such as GB/T 23257-2017 Annex K, ISO 21809-1, and CSA Z245.21 to ensure that the testing procedures and results are globally accepted and comparable.

2. Precision Sensing and Control: The pipe coating peeling tester must be equipped with high-precision sensors, maintaining an error margin within ±2% to guarantee accurate measurements of peel strength. Automated control of peeling rate and angle is essential to ensure consistency and repeatability of tests.

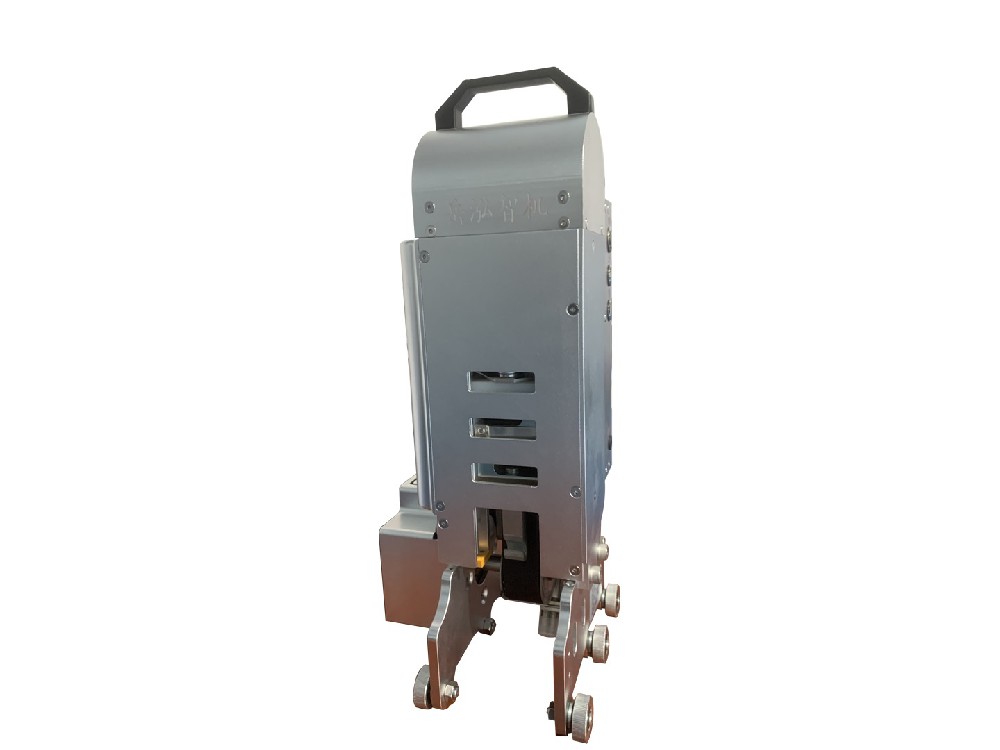

3. Portability and Durability: The design should balance portability with durability. The coating peeling tester should be compact and lightweight for easy transportation between sites. High-strength aluminum alloys are preferred for their robustness and long-term stability.

4. Intuitive Interface: A user-friendly touchscreen interface is crucial for ease of use. Wireless capabilities such as Bluetooth or infrared connectivity should be included to enhance the device's utility in the field.

5. Data Management and Storage: Real-time collection, display, and storage of critical parameters like peel rate, displacement, force, time, and temperature are necessary. The device should have substantial built-in storage to archive extensive data and support wireless uploading and export functions.

6. Environmental Adaptability: The pipe coating peeling tester must perform reliably across diverse environmental conditions, including high temperatures, humidity, and dust, ensuring operability even in harsh work settings.

7. Safety and Environmental Consideration: Materials and processes used in the device should meet environmental standards, and the operation should be safe to prevent potential hazards to users and the environment.

8. Technical Support and Service: Comprehensive technical support and services for installation, calibration, maintenance, and training should be provided by the supplier to ensure efficient operation of the equipment.

These requirements summarize the expectations for a state-of-the-artpipeline anti-corrosion coating testing device and are perfectly aligned with the capabilities of our product. Our equipment not only meets these demands but also sets a new benchmark in the industry, underscoring its unique value proposition for prospective users in the engineering field.

Specification item | Technical Index | Specification item | Technical Index |

Standard compliance | GB/T23257-2017,ISO21809-1,CSAZ245.21 | connectivity | Infrared built -in memory |

Sensor accuracy | ±2% | Data storage | Caale of storing data for over 1000 tests supports |

Peeling rate | Adjustable automatic control | Data output | Wireless data upload and export |

Peeling angle | Adjustable, precise control≤kg | Environmental adaptability | Stable operation in high temperature humidity, and dust |

material | High-strength aluminum alloy | Power supply | Battery supports extended operation |

User interface | Touch screen | Safety and environment standard | Complies with relevant environmental and safety regulations |

Wireless connectivity | Bluetooth or infrared | Technical support | Installation calibration,maintenance and training services provided |

Contact Us

Contact:Jenny Lee

Tel:+86-13132401909

Tel:+86-13132401909

Email:shirley9@pipesitesolution.com

Address: Zhongguancun Industrial Collaborative Innovation Base, Hengshui City, Hebei Province